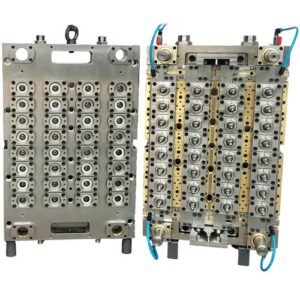

Preform Moulds with Hot Runner and Temperature Controllers

We also provide Multi Cavity preform moulds with the technology called “Hot Plate” Preform Moulds. Its uses a Spring Loaded Shut off Needle to close the gate Point. The Manifolds are fully balanced to give optimum material flow and cartridge heaters are provided to maintain the Manifold Temperatures.

Our precisely balanced Hot Runner ensures uniform Material distribution and Uniform heating ensure the AA levels and material flows are maintained in the manifold from cavity to cavity.

Our Cold Half design ensure the preforms quality and wall thicknesses are maintained within the permissible limits per the international standards.

The Turbulent Cooling design ensure optimum / reduced cooling time which results in better productivity and performance.

We ensure the mould life is not compromised during designing and our customers get maximum mould life with optimum Cycle times.

Our R&D in Mould Designing and Manufacturing practices helps us to provide our Hot Runner Mould at a “highly competitive prices” without any compromise in Raw materials or Design.